That's where the Ream Clipper comes in. You can see the illustration in the following video.

It is possible to stack items without peeling the wamp without lifting the paper.

By connecting a stacker, it is possible to dramatically improve the efficiency of blank sheet cutting work.

In addition, the slide table allows you to efficiently feed paper into the cutting machine.

NJ Series

Automatic paper sorting machine for cutting industry.

The air blowing function and air discharging mechanism can improve not only work efficiency in the field but also the finish quality.

● Uniform air discharging with two rollers

● One-touch control of right tilt and left tilt

● Two inclination angles

● Strong air discharging mechanism:

By removing the air from the paper, the post-process = the operating rate of the cutting machine is increased, and the finished quality is also improved.

●Prevention of paper smearing : The forward and reverse rotation of the vibration motor can be selected by the paper quality, left needle, and right needle.

●Paper separation device (optional): Helps the paper separation by introducing air from two abutting surfaces

● Static eliminator (option) : The static eliminator suppresses the sticking of paper due to static electricity and helps the paper separation.

Size, Compatibility with Cutting Machine

- NJ-130

- Applicable size: A times, recommended to use with Hatron size extension 137 cutting machine.

- Air blowing up to 1,456 mm in width.

- NJ-100

- Applicable sizes: All 46, All B, Hatron 116.

- It fits right next to the cutting machine.

- Air blowing up to 1,292 mm in width.

- NJ-90

- Correspondence size: Kikuzen, All A,46 half cut.

- The smallest in the series. Compact and space-saving.

- 102 fits right next to the cutting machine.

- Removes air with a frontage width of up to 1,162 mm.

Pile Ruck

Feeding Stacker

● A paper feed device dedicated to skits.

From the back side of the cutting machine, a certain amount is transferred onto the cutting machine table using an air gun.

● Used as a set with the grip feeder.

● You can easily lift the paper with the table lifter.

● If you fill the table lifter in the pit construction, you can easily handle the high pile of paper.

Grip Feeder

● Supports a single feed height of up to 170 mm.

● Hold the jogger and pile rack paper firmly and automatically transfer it while bleeding air. Paper is automatically fed from the back of the cutting machine.

● Two grips prevent the paper from being pulled or bent.

A safe design that stops the operation of the back gauge of the cutting machine if there is a problem with the grip.

● If you work with two people, you can cut without interruption, and the operating rate of the cutting machine will improve to 150%.

● Since the paper is fed backward, the installation space is reduced.

LV-100E

Lift up automatically and can be used directly in that way

It has a small turn and can be easily handled even in the field.

Since it can be lifted larger than the hand pallet lift, paper can be put into the cutting machine while it is raised.

・A hand lift that is convenient for moving paper

・Up / down with a simple lever operation. The ascending / descending speed can also be adjusted with a single lever

・Battery-powered, No trouble to connect the power source.You can go anywhere, anytime without any cable connected on

・Automatic rise sensor can also be installed (Optional)

NSL Series

Strong Support for Loading and Unloading Paper

Cooperative support for loading and unloading work! !!

-Equipped with an auto-lift function that raises the amount of paper removed and lowers the amount of paper placed.

-A safe design with sensor detection even if your foot gets under the lift.

-Easy loading and unloading with hand pallets even in factories where forklifts and platters cannot be used.

-There is no need for installation work to be embedded in the ground like a pantograph type lifter.

| Model | NSL-90 | NSL-100 |

| Backup Size(mm) | 1,066×658 | 1,216×810 |

| Maximum Load(kg) | 1,000 | 1,000 |

| Lifting Stroke(mm) | 800 | 800 |

| Lifting Speed(mm/sec) | ~30 | ~30 |

| Required Power(kW V) | 0.4 200 3 Phase | 0.4 200 3 Phase |

| Machinery Dimension(mm) | 1,288×1,028×1,540 | 1,438×1,178×1,540 |

| Weight(kg) | 320 | 350 |

NHL-130

Powerful Lift even on Large Paper

Even large size goes up firmly! !!

- -Equipped with an auto-lift function that raises the amount of paper removed and lowers the amount of paper placed

-Easy loading and unloading with hand pallets even in factories where forklifts and platters cannot be used

-There is no need for installation such as embedding in the ground like a pantograph type lifter

-The pallet can be placed with a hand lift - (Maximum Pallet Size 1300 x 900mm)

-Hydraulic system supports up to 1 ton

-There is no need for installation work to be embedded in the ground like a table lifter

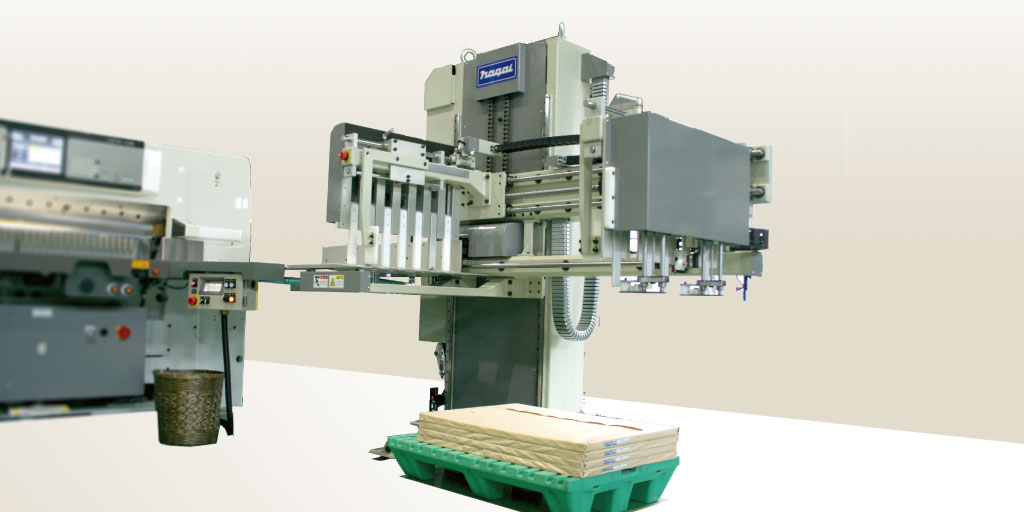

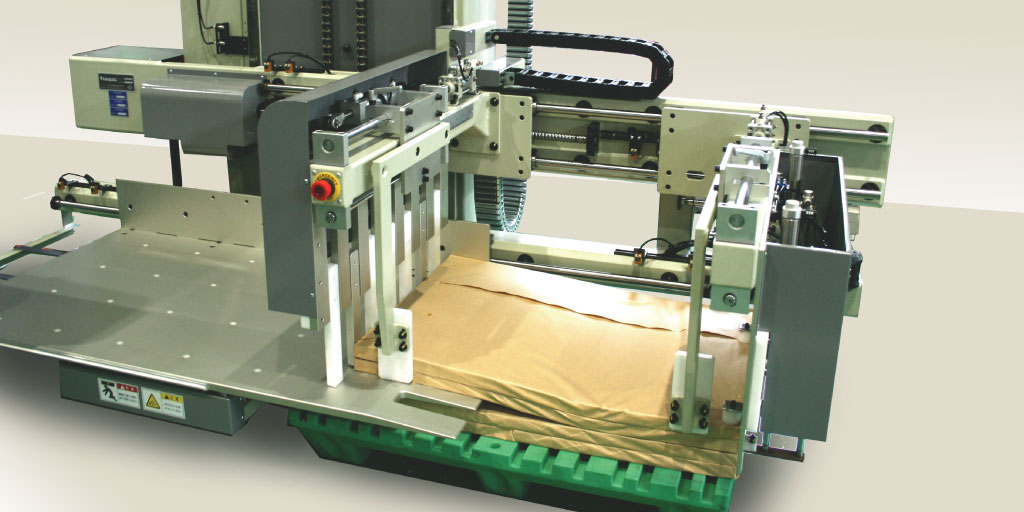

Double Pile Paper Stacker

● Paper that has been cut is automatically stacked on the pallet.

For example, half-cut blank paper can be stacked on two pallets with high precision.

● Four paper grip claws (chucking) firmly catch the longitudinal direction.

With the horizontal twist function (utility model notification has been submitted), it can be properly laid down.

● Since the stick stacking accuracy is good, it can be set directly on the feeder of a printing machine or paper folding machine without stacking by hand.

● The operating rate of cutting is 1.5 to 2 times that of manual loading.

● Since it can be stacked without bending over, the burden on the operator is reduced.

B-Size All Compact Paper Stacker

Sizes of Compact Paper Stacker

A

Overall Length

3,000mm

I

Maximum Frontage

1,258mm

B

Dimensions behind the center of the main body

1,270mm

J

530mm

C

Dimensions in front of the center of the main body

1,732mm

Maximum Paper Size

1,100×800mm

D

Overall Breadth

1,435mm

Minimum Paper Size

550mm

E

Air-Table Breadth

800mm

Maximum Height for 1Rim

165mm

F

Air-Table Length

1,320mm

Maximum Height(Pallet Included)

1400mm

G

Overall Height

2,055mm

Required Power

1.8kW

H

Maximum Height(When table rises)

2,150mm

Total Weight

2,000kg

Paper Stacker

- ●Excellent Stacking Accuracy : Easy to use for both blank paper and printing paper

- ●Reduces the burden of manual work and improves the operating efficiency of the cutting machine.

- ●No need for digging

- ●Designed for pallet center loading and puddle loading

- ●The puddle stacking, gripper straightening device, and horizontal offset device are optional specifications

Specification Table

| Model | NJ-90 | NJ-100 | NJ-130 |

| Paper Sizes(mm) | Kiku Full/Half | Forty-Six Full/Half | A |

| Table Sizes(mm) | 979×700 | ツ黴1,109×800 | 1,269×900 |

| Sizes(mm) | 170 | 170 | 170 |

| Air Discharged Height (mm) | 20~165 | 20~165 | 20~165 |

| Required Power(W) | 1,670/1,710 200V 3Phase | 1,820/1,860 200V 3Phase | 1,820/1,860 200V 3Phase |

| Mechanical Dimension(mm) | 1,162×921×1,743 | 1,292×1,021×1,743 | 1,452×1,141×1,743 |

| Weight(kg) | 410 | 460 | 510 |